by Patti Dees

No matter what kind of HVAC system you have, investigate the causes behind signs of a cracked heat exchanger. At a minimum, cracks reduce efficiency and increase waste. More concerning are the potential hazards to occupants and, in some cases, the community. While most cracked exchangers are caused by normal wear and tear, learning the signs can give managers and maintenance staff a way to stay ahead of the problem.

Why Heat Exchangers Matter

Without a heat exchanger, there is no HVAC system. Heating and air conditioning rely on heat exchangers to move heat to and from temperature-controlled areas. Some types of heat exchangers found in HVAC include boilers, chillers, microchannel heat exchangers (MCHE), furnaces and chilled beams. The heat sources and fluids used to move heat through these exchangers include a variety of materials such as water, steam, electricity, geothermal sources, refrigerant, air, and furnace fuel. A stand-out HVAC design combines the equipment and fluids best suited to meet efficiency, safety and performance needs. Damaged heat exchangers limit the system’s ability to meet those needs.

Loss of fluids from cracks impact efficiency and performance but can also create hazards for occupants and maintenance staff. Air or other fluids entering or leaving an HVAC system through a cracked heat exchanger skews the temperature and creates undesirable pressure changes. As pumps and fans work harder to compensate for these unexpected changes, efficiency falls and waste increases. For example, escaping steam from a boiler siphons heat out of the system into undesired locations. It also creates a burn hazard and a moist environment for mold to flourish. The goal is to keep the steam from escaping, but if it happens anyway, catching the issue as soon as possible can limit the overall cost of the repair.

Loss of fluids from cracks impact efficiency and performance but can also create hazards for occupants and maintenance staff. Air or other fluids entering or leaving an HVAC system through a cracked heat exchanger skews the temperature and creates undesirable pressure changes. As pumps and fans work harder to compensate for these unexpected changes, efficiency falls and waste increases. For example, escaping steam from a boiler siphons heat out of the system into undesired locations. It also creates a burn hazard and a moist environment for mold to flourish. The goal is to keep the steam from escaping, but if it happens anyway, catching the issue as soon as possible can limit the overall cost of the repair.

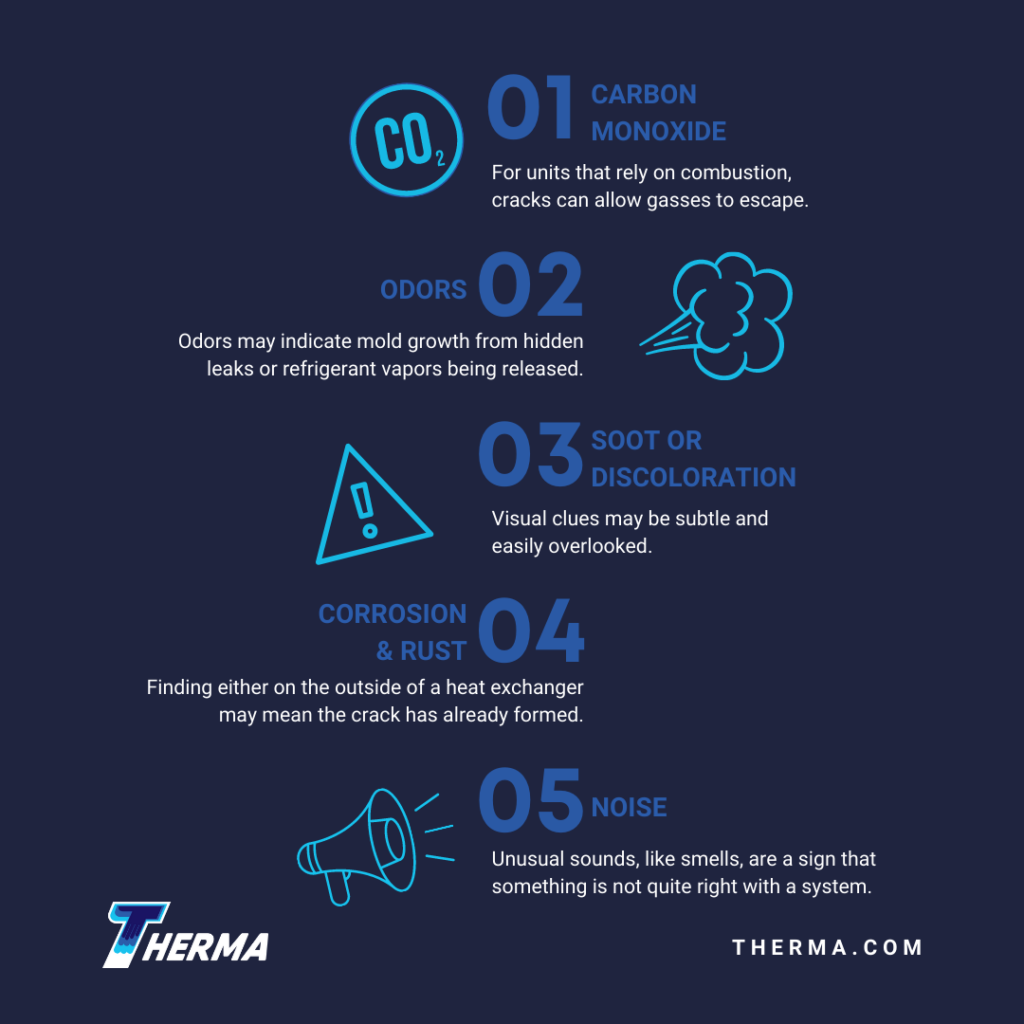

5 Signs of a Cracked Heat Exchanger

Some of the signs of a cracked heat exchanger depend on the type of HVAC system and the location of the heat exchanger within the system. For instance, carbon monoxide — a byproduct of burning fuel found in flue gasses — is probably not going to leak from an exchanger unless its system uses combustion to generate heat.

-

Carbon Monoxide

For units that rely on combustion, cracks can allow gasses to escape. If testing and monitoring indicates that CO levels are elevated, the heat exchanger should be inspected for cracks.

-

Odors

Odd smells from combustion-based systems may be signs of flue gas or furnace fuel escaping. They can also indicate an issue for HVAC systems that are not designed for combustion. Odors may indicate mold growth from hidden leaks or refrigerant vapors being released.

-

Soot or Discoloration

Visual clues may be subtle and easily overlooked. Escaping flue gases can cause discoloration from soot. Water spots are also telltale signs that something may not be right with a nearby heat exchanger.

-

Corrosion and Rust

Corrosion and rust are not good signs for any heat exchanger. Finding either on the outside of a heat exchanger may mean the crack has already formed. Finding them within a heat exchanger can point to areas to watch as the damage may progress further, creating the perfect place for a crack to form in the future.

-

Noise

Unusual sounds, like smells, are a sign that something is not quite right with a system. Investigate new pinging, rattling, whistling or any sound out of the ordinary as it could indicate metal giving way or sudden changes in pressure.

Common Causes of Cracked Heat Exchangers

Common Causes of Cracked Heat Exchangers

The most common culprit for damaged heat exchangers is simply regular wear in aging equipment. As materials heat and cool, they expand and contract. The stress from repeated cycling eventually takes its toll and cracks form. The best way to combat age-related cracking and extend the life of your equipment is preventive maintenance.

Other than equipment at the end of its life cycle, heat exchangers can also be damaged through accidents, negligence and poor design. An example would be an improperly designed system that requires more frequent cycling or depends on overheating a heat exchanger to maintain a desired set point. While some expansion during heating is expected, excessive heat actually weakens the material, shortening the equipment’s life cycle, and can even lead to catastrophic failure. Other causes include increased pressure from fluids, clogged tubes or filters and corrosion.

Staying Ahead of the Damage

Unfortunately, damage to heat exchangers cannot be completely avoided. But vigilance can help put off the inevitable and limit expensive repairs. Learning common signs of cracked heat exchangers and incorporating applicable monitoring and inspections into preventive maintenance (PM) plans is a proactive method of avoiding system waste and potential hazards. A good PM plan can limit situations that could lead to overheating, blockages and corrosion. It can also include monitoring for CO, moisture or other signs that rapid repairs are needed.

Professionals at Therma provide design, installation and maintenance services for HVAC systems as well as for building management systems (BMS) and automation solutions that can safeguard occupants and prevent excessive damage to HVAC heat exchangers.

Patti draws on her background as a chemical engineer to share information with readers on technology, manufacturing, and construction.

Sources

HVAC School – Heat Exchanger Crack Diagnosis

FacilitiesNet – 4 Ways to Wreck Your Boiler

Heat Exchanger Experts Inc – The Dangers of a Damaged Heat Exchanger