by Ali Kriscenski

Industrial dust collection systems remove airborne particles out of facility workspaces. They can provide a number of benefits and have a positive impact on health and safety, efficiency and operating costs. In this article we’ll take a look at how these systems work, and whether your facility could benefit from a dust collection system.

How Dust Collection Systems Work

Dust collection systems create facility-wide airflow patterns that help remove particles created by industrial and manufacturing processes. These systems create a low-pressure zone within the dust collection unit similar to a vacuum used for cleaning surfaces. Fans draw particles out of the air and into the collection units with centrifugal force. Once removed from the air, the hazardous particles are collected in various types of filters and filter bags.

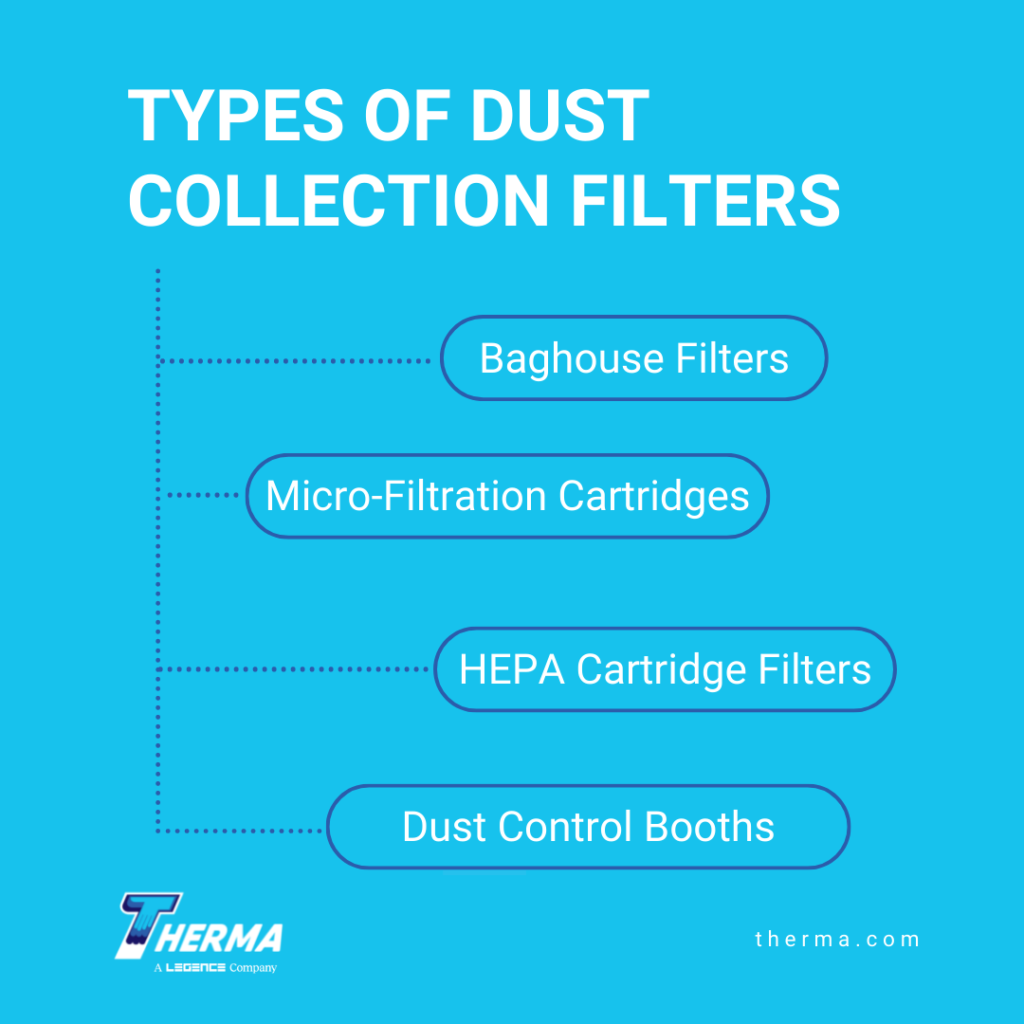

Types of Dust Collection Filters

Baghouse filters are optimal for collecting heavy dust loads, such as those from woodworking, plastics or metals. These filters are large “bags” through which the vacuumed air passes. The bag material can be made of durable, temperature-resistant products that can remove high-temperature pollutants and store them safely for cooling and disposal.

Micro-filtration cartridges are able to capture finer particles than baghouse filters and can safely remove particles to 0.5 micron. This mid-range size particle can include pollutants such as tobacco smoke or metallic fumes, and can be useful to create higher air quality for specialized facilities.

HEPA (high-efficiency particulate air) cartridge filters work to remove particles 0.3+ microns in size. This filter is suitable for applications where pharmaceuticals or carcinogenic materials are being processed. HEPA filters are highly effective at removing and capturing particulates, and can be utilized to maintain cleanroom standards.

Dust control booths are ideal solutions to remove dust, smoke and fumes from high-volume manufacturing or processing facilities. These systems can provide a more localized dust control option within a larger facility. They can be fitted with cartridge or wet filters to control contaminants in metal fabrication, stone fabrication, sawmills or woodworking.

Which Industries Benefit from Dust Collection Systems

While dust collection is important to maintain health and safety compliance in any facility, there are many industries where dust collection systems are critical. These include woodworking, agriculture, food processing, pharmaceutical, cement and stone, metal fabrication and chemical processing. The particles created in the industrial processes of these industries can produce acute or chronic respiratory and skin illnesses, or injuries. Industries that deal with controlled substances, such as pharmaceutical manufacturing, can create toxic particulates with caustic or fatal indications.

Understanding Relevant Industry Regulations

Because of the health and safety implications that airborne particles create, dust collection systems are regulated by a number of government and industry guidelines. These include the U.S. Environmental Protection Agency (EPA), U.S. Occupational Health and Safety Administration (OSHA), and the National Fire Protection Association (NFPA).

The guidance and regulations from these organizations are intended to protect workers and the environment. While OSHA does not specify that a dust collector is needed, the standard does require engineering controls of contaminants where the hazards cannot be removed. OSHA sets limits for dust exposure which can be maintained with properly maintained dust collection systems.

Where dust accumulation poses a fire hazard, the NFPA standards provide guidance for managing combustible dust. The standards are overseen by OSHA and local fire and safety authorities, and are also referenced in most insurance policies. While dust collection systems can help facilities stay in compliance with regulations, non-compliance can result in fines or citations which may impact safety ratings and insurance costs.

The EPA regulates the release of pollutants into the environment to protect water, air, ecosystems and human health. Air pollution control is a requirement for companies that create particulates through processing or manufacturing. These can include metal products; paints and pigments; minerals such as coal, cement, or stone; and agricultural materials, such as grains.

Dust Collection Systems Maintenance

Whether you are considering a new dust collection system, or surveying an existing system, proper maintenance is key to ensuring your system is working properly. An industry expert can help you assess current equipment for preventative maintenance, or design a custom system to meet your facility’s specific dust control requirements. Contact an expert at THERMA today.

Ali Kriscenski was trained in high-performance building design at Boston Architectural College. She has worked with leading architecture and construction firms in NYC and New England and served on the executive team at the Forest Stewardship Council International. She was the managing editor at Inhabitat and has worked pro bono for the Green Building Institute, ISEAL Alliance and Habitat for Humanity.

Sources

Industrial Safety & Hygiene News – Capture Airborne Particles to Protect Worker Health

OSHA – Indoor Air Quality